Driving Innovation with

Automated Manufacturing

United Industries Groupas the first company being incorporated for UI Group. In the mid 70’s, the company managed to penetrate into the Original Equipment Manufacturer (OEM) market by supplying its exhaust systems to Asia Automobile Industries Sdn. Bhd.

Welcome to United Industries Group

Driving Innovation with

Automated Manufacturing

United Industries Groupas the first company being incorporated for UI Group. In the mid 70’s, the company managed to penetrate into the Original Equipment Manufacturer (OEM) market by supplying its exhaust systems to Asia Automobile Industries Sdn. Bhd.

Kaizen

Customers

UNITED INDUSTRIES SDN. BHD.

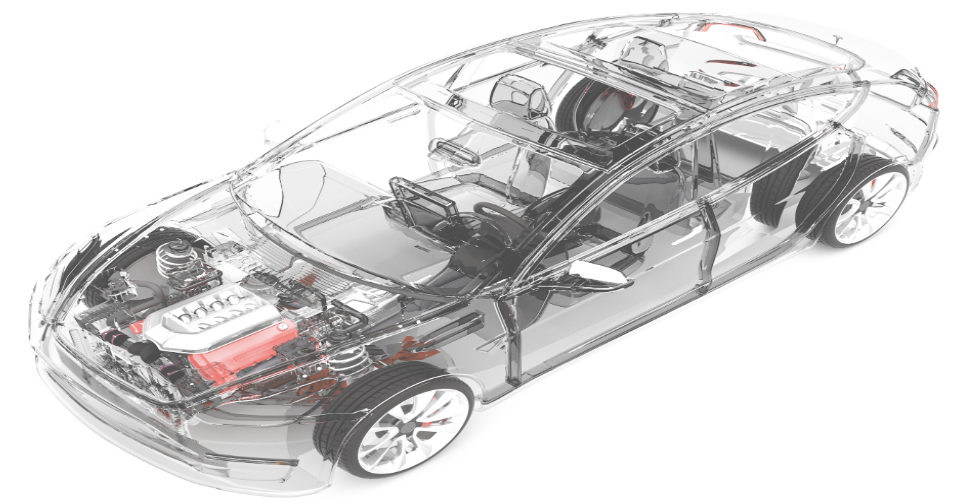

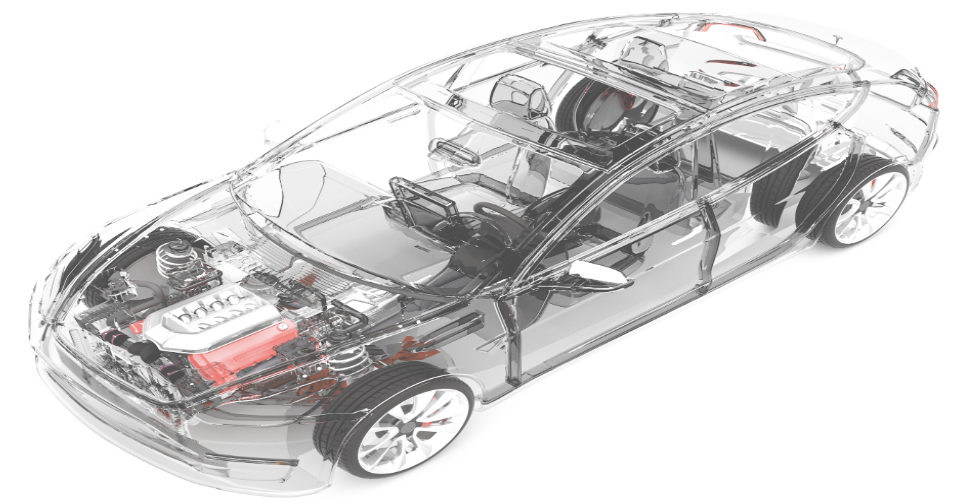

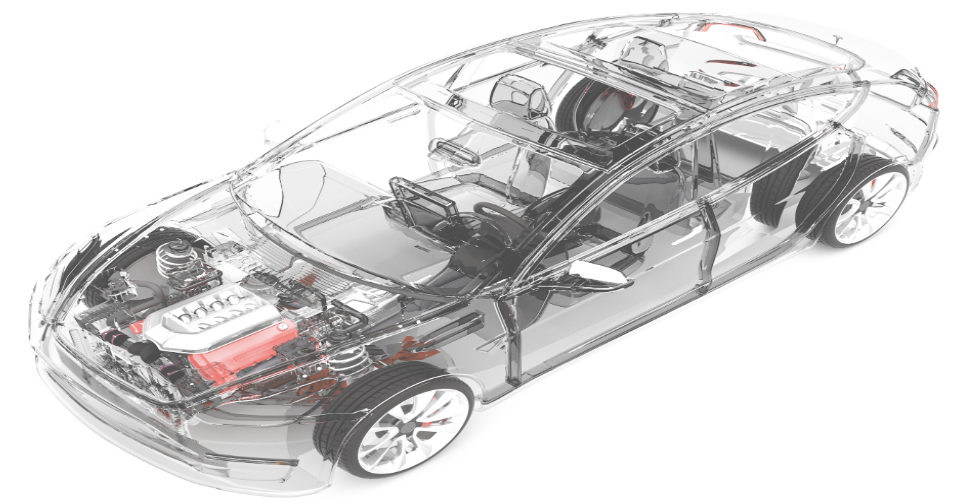

Product Overview

Reinforcement Instrument Panel

![]()

Support Assy Hood

Battery Clamp

![]()

Clamp Clutch Cable

Rod Fr Door Lock Open

Rod Rr Door Lock Open

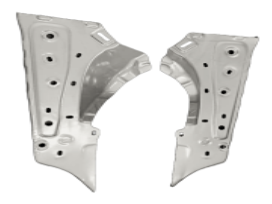

Reinforcement Side Member

United Industries Sdn. Bhd. was incorporated on 28 February 1973 and it was the first company that was incorporated by UI Group. In the mid 70’s, the company ventured into the Original Equipment Manufacturer (OEM) market by supplying its exhaust systems to Asia Automobile Industries Sdn. Bhd.

Thereafter, other car assemblers follow suit to become customers of United Industries Sdn. Bhd. The company has expanded into the manufacturing of other automotive parts, like beam axle, lateral rod, battery clay, etc.

Presently, United Industries Sdn. Bhd. is focusing in the manufacturing of cross center beam and tubular related products for OEMs in Malaysia. Plans are underway to expand our capacity and capabilities with new projects from Perodua and Honda.

United Vehicles Industries Sdn. Bhd. was incorporated on 7 September 1982 and commenced its operations as a fuel tank manufacturer in 1984. In Year 1985, the company managed to secure the contract to supply its fuel tanks for Malaysia’s first national car, Proton Saga. Subsequently, supplied to majority of the car manufacturers or assemblers.

In Year 2002, the company participated in the development of plastic fuel tank with technical collaboration with Kautex Textron GmbH & Co., Germany. The company then set up a plastic blow moulding facilities in Malaysia to produce and supply plastic fuel tank for Proton Waja model. The company was also able to export over 50,000 plastic fuel tanks to General Motors, China in 2010.

In addition, the company also produce stamping parts, such as cross member assembly, floor cross, support radiator, and many more.

With the recent technical collaboration with Yachiyo Industry Co., Ltd., Japan, it strengthen our experience and capability to supply plastic fuel tank to OEMs in Malaysia and the company investing into a new plant in Pegoh to cater for its demand.

UNITED VEHICLES INDUSTRIES SDN. BHD.

Product Overview

Butterfly Panel Cowl Top Side

Transmission Case

Cross Member

Bracket Engine

Mounting

Butterfly Panel Cowl Top Side

Center Member

Plastic Fuel Tank

Metal Fuel Tank

Jack S/A Pantograph

UNITED SANOH INDUSTRIES SDN. BHD.

Product Overview

Tube Assy Engine Compartment

Water Cooler Pipe

Oil Level Gauge

Tube Assy Fuel

Tube S/A Fuel

Tube Fuel Suction

Tuba S/A Evaporation

Neck Assy Filler

Brake Tube

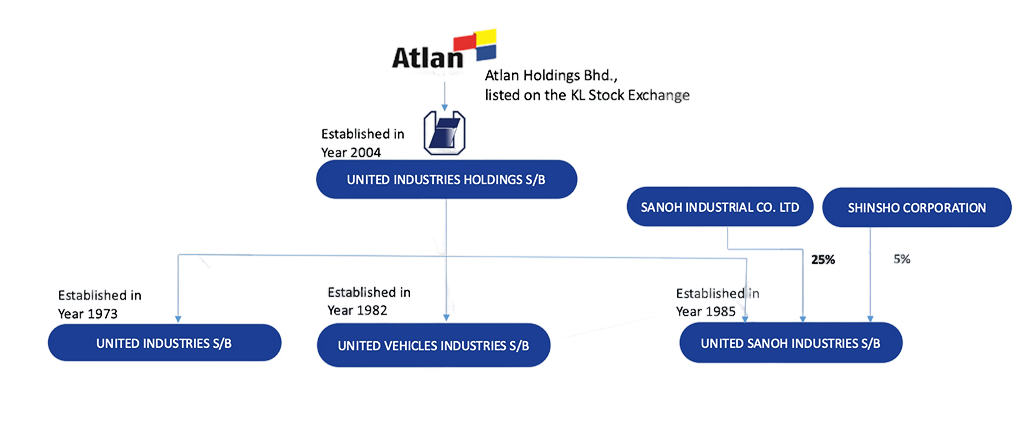

United Sanoh Industries Sdn. Bhd. was incorporated on 26 July 1978 and it is a joint venture between UI Group, Sanoh Industrial Co., Ltd. and Shinsho Corporation, Japan.

The company commenced its operations in 1985 to manufacture brake, fuel clutch and power steering tubing, fuel tank pipes, fuel filler necks, water inlet pipes, etc with technical assistance provided by Sanoh Industrial Co. Ltd., Japan.

Together with United Vehicles Industries Sdn. Bhd., the company is expanding its operation into a new plant at Pegoh where the location is near to Honda Malaysia and target to commence operation in year 2021.

About Us

United Industries Groups the first company being incorporated for UI Group. In the mid 70’s, the company managed to penetrate into the Original Equipment Manufacturer (OEM) market by supplying its exhaust systems to Asia Automobile Industries Sdn. Bhd.

Remain a Strong Malaysian Owned Automotive Components Manufacturer through:

WHO WE ARE

We focus in manufactory automation

Years of Experience

OUR VALUE

Our Vision

Our vision is to be profitable, to fund investment and growth and to be meaningful for the future and our shareholders.

Our Mission

Our mission is to become a first-tier supplier and market leader through innovative, cost-competitive manufacturing, powered by the best-trained workforce in the industry.

Our Values

Our value is to maintain simple and transparent processes, empower employees as owners of their work, continuously invest in process innovation, and cultivate respect with all stakeholders.

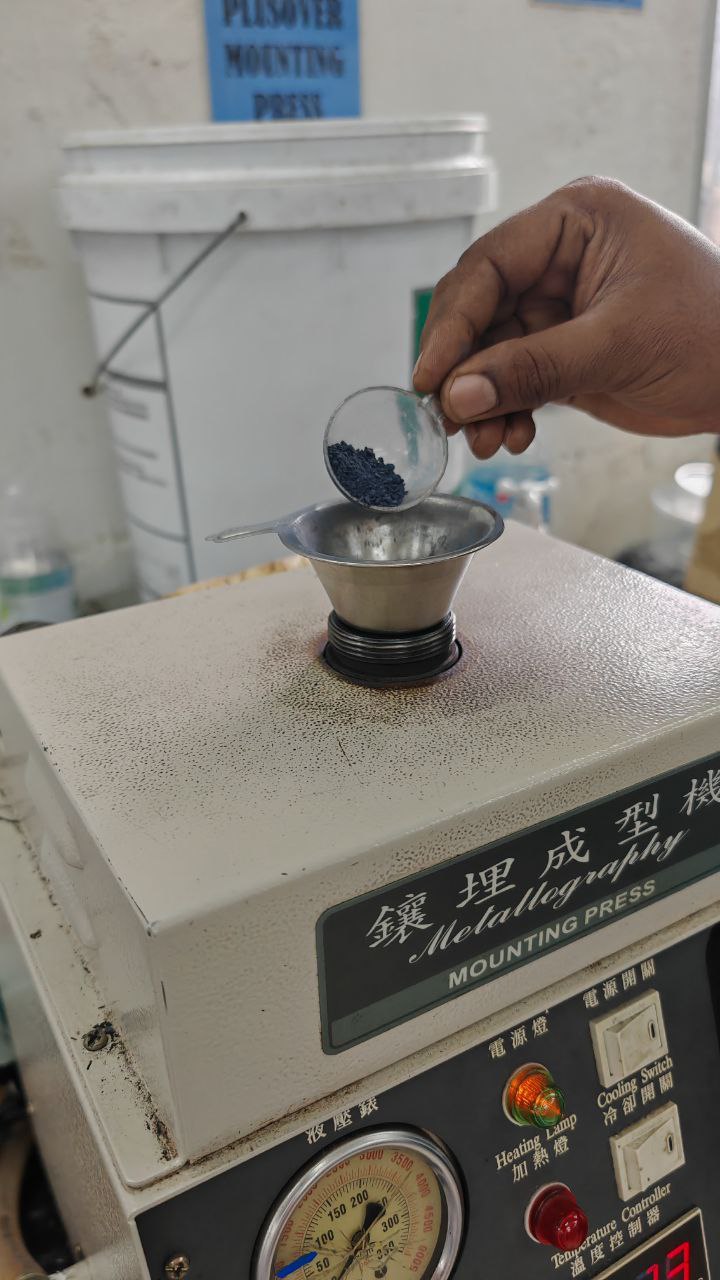

Quality Control and Monitor

Our customers throughout the world to use our products with even greater confidence, We obtained certification stating compliance with international standards ISO 9001 and ISO 14001, guaranteeing a reliable system of quality assurance and environmental management. We strives to develop products to meet customer expectations and contributions to society.

Manufacturing Process

![]()

Initiation

![]()

Development

![]()

Operation

![]()

Storage

![]()

Final

Incorporated UISB to take over the business of Syarikat United Industries, a partnership business entity founded since 1968.

成立UISB,接管自 1968年以來成立的合 夥企業Syarikat United Industries的業務

UISB shifted from a cottage-like factory to its present location and expanded to Original Equipment Market (OEM) in the automotive industries.

UISB從一間小屋式的工廠發展 到現在的位置,並擴展到汽車 行業的原始設備市場(OEM)

Expanded into wheel barrow maker under the brand name “DANCO”. 以「DANCO」品牌擴 大為手推車製造商。

Joint venture with Sanoh Industrial Co. Ltd. For tubing system & Entered into TA with J.Ebërspacher GmbH & Co, Germany for exhaust system for Daimler-Benz 與Sanoh Industrial Co. Ltd.成立 合資公司油管系統 & 與德國 J.Ebërspacher GmbH & Co 簽訂 TA 協定,為戴姆勒-賓士提供排 氣系統

Entered into Technical Assistance Agreement (“TA”) with Crefact Corporation, Japan (formerly known as Sankei Industry Co. Ltd. Japan) for metal fuel tank 與日本Crefact株式會 社(前身為日本產經 工業株式會社)簽訂 金屬油箱技術援助協 定(“TA”)

Entered into Technical Assistance Agreement (“TA”) with Crefact Corporation, Japan (formerly known as Sankei Industry Co. Ltd. Japan) for metal fuel tank 與日本Crefact株式會 社(前身為日本產經 工業株式會社)簽訂 金屬油箱技術援助協 定(“TA”)

Entered into TA with J.Ebërspacher GmbH & Co, Germany for exhaust system for Auto BavariaBMW 與德國J.Ebërspacher GmbH & Co簽訂TA協定, 為巴伐利亞寶馬汽車公 司提供排氣系統

Entered into TA with KAUTEX Textron GmbH & Co, Germany for plastic fuel tank 與德國KAUTEX Textron GmbH & Co簽訂塑膠油箱 TA協定

Certified ISO 9001 認證

Entered into TA with Sejong Industrial Co. Ltd., Korea for exhaust system and Kumpa Corporation Co. Ltd., Korea for tubing system 與韓國世宗工業株式會 社簽訂排氣系統技術援 助協定,與韓國Kumpa Corporation Co., Ltd.簽 訂油管系統技術援助協 定

Atlan Holdings Bhd, a public listed company on the Malaysia Stock Exchange completed the acquisition of United Industries Group. Atlan Holdings Bhd是一家在 馬來西亞證券交易所上市的 公司,完成了對 UI Gp的收購。

Certified ISO/TS 16949:2009, EMS 14001:2004 and OHSAS 18001:2007 通過 ISO/TS 16949 :2009、EMS 14001:2004 和 OHSAS 18001: 2007 認證

Entered into TA with Yachiyo Industrial Co. Ltd. 與Yachiyo Industrial Co., Ltd.簽訂技術 助理合同。 (qiāndìng jìshù zhùlǐ hétong)

Certified ISO 9001:2015, IATF 16949:2016 and EMS 14001:2015 OHSAS 18001:2007 認證

Entered Technical Assembly with Plastic Omnium Auto Inergy 與Plastic Omnium Auto Inergy一起進入 技術組裝

Concluded TA with BESTEX Kyoei Co., Ltd. Japan for Pipe Fuel Filler 與日本BESTEX Kyoei Co., Ltd. 簽訂管道燃料填 料技術援助協定

01

2 Plants (Klang, Selangor & Pegoh, Malacca)

2個工廠(巴生,雪蘭莪州 – 距離機場40公里,馬六甲州佩戈,距離巴生137公里)

02

2 Plants (Klang, Selangor & Pegoh, Malacca)

2個工廠(巴生,雪蘭莪州 – 距離機場40公里,馬六甲州佩戈,距離巴生137公里)

03

368,000++ sq ft Plant Size 平方英尺 廠房面積

04

1 Joint Venture (1家合資企業)

05

8 Technical Partners (8 技術合作夥伴)

06

900++ Manpower (員工)

United Industries Group Organisation Chart

1. Designing

The part is designed using SolidWorks or ZWCAD. Then, tooling is created and adjusted. CAMWorks or Mastercam makes the toolpaths for the CNC machine. Quick Press is used to create the die, and a prototype is tested. Simulations help fix any issues before production.

2. Tooling / Die Assembly

The individual components of the die are made and tested for fit. After that, CAMWorks or Mastercam is used to create toolpaths for CNC machining. The die parts are then assembled, and the complete die is tested to ensure it works correctly.

3. Quality Testing / Improvement

The die or tooling is tested by creating a prototype and checking how it works. If there are any issues, the design is adjusted. After fixing problems, it’s tested again to make sure it works right. Once it’s good, the tooling is ready for production.

4. Mass Production

In mass production, the die or tooling is set up in machines to make lots of parts. Quality is checked regularly, and any problems are fixed. Once everything works well, production continues until parts are made.

Partner with us for cutting-edge manufacturing solutions.

Experience the future of automation and innovation today!