UNITED INDUSTRIES SDN. BHD.

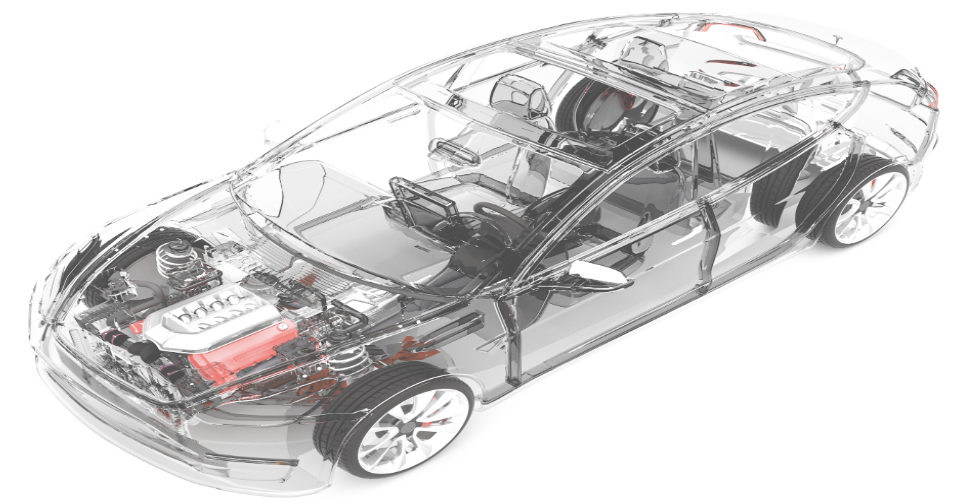

Product Overview

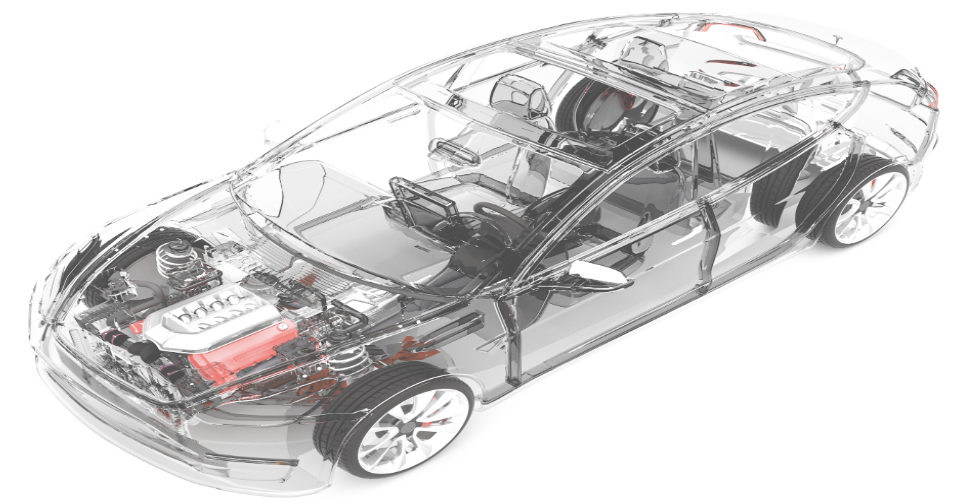

Reinforcement Instrument Panel

![]()

Support Assy Hood

Battery Clamp

![]()

Clamp Clutch Cable

Rod Fr Door Lock Open

Rod Rr Door Lock Open

Reinforcement Side Member

United Industries Sdn. Bhd. was incorporated on 28 February 1973 and it was the first company that was incorporated by UI Group. In the mid 70’s, the company ventured into the Original Equipment Manufacturer (OEM) market by supplying its exhaust systems to Asia Automobile Industries Sdn. Bhd.

Thereafter, other car assemblers follow suit to become customers of United Industries Sdn. Bhd. The company has expanded into the manufacturing of other automotive parts, like beam axle, lateral rod, battery clay, etc.

Presently, United Industries Sdn. Bhd. is focusing in the manufacturing of cross center beam and tubular related products for OEMs in Malaysia. Plans are underway to expand our capacity and capabilities with new projects from Perodua and Honda.

United Vehicles Industries Sdn. Bhd. was incorporated on 7 September 1982 and commenced its operations as a fuel tank manufacturer in 1984. In Year 1985, the company managed to secure the contract to supply its fuel tanks for Malaysia’s first national car, Proton Saga. Subsequently, supplied to majority of the car manufacturers or assemblers.

In Year 2002, the company participated in the development of plastic fuel tank with technical collaboration with Kautex Textron GmbH & Co., Germany. The company then set up a plastic blow moulding facilities in Malaysia to produce and supply plastic fuel tank for Proton Waja model. The company was also able to export over 50,000 plastic fuel tanks to General Motors, China in 2010.

In addition, the company also produce stamping parts, such as cross member assembly, floor cross, support radiator, and many more.

With the recent technical collaboration with Yachiyo Industry Co., Ltd., Japan, it strengthen our experience and capability to supply plastic fuel tank to OEMs in Malaysia and the company investing into a new plant in Pegoh to cater for its demand.

UNITED VEHICLES INDUSTRIES SDN. BHD.

Product Overview

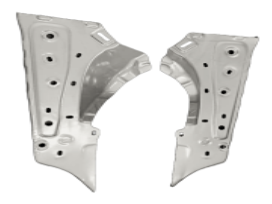

Butterfly Panel Cowl Top Side

Transmission Case

Cross Member

Bracket Engine

Mounting

Butterfly Panel Cowl Top Side

Center Member

Plastic Fuel Tank

Metal Fuel Tank

Jack S/A Pantograph

UNITED SANOH INDUSTRIES SDN. BHD.

Product Overview

Tube Assy Engine Compartment

Water Cooler Pipe

Oil Level Gauge

Tube Assy Fuel

Tube S/A Fuel

Tube Fuel Suction

Tuba S/A Evaporation

Neck Assy Filler

Brake Tube

United Sanoh Industries Sdn. Bhd. was incorporated on 26 July 1978 and it is a joint venture between UI Group, Sanoh Industrial Co., Ltd. and Shinsho Corporation, Japan.

The company commenced its operations in 1985 to manufacture brake, fuel clutch and power steering tubing, fuel tank pipes, fuel filler necks, water inlet pipes, etc with technical assistance provided by Sanoh Industrial Co. Ltd., Japan.

Together with United Vehicles Industries Sdn. Bhd., the company is expanding its operation into a new plant at Pegoh where the location is near to Honda Malaysia and target to commence operation in year 2021.

1. Designing

The part is designed using SolidWorks or ZWCAD. Then, tooling is created and adjusted. CAMWorks or Mastercam makes the toolpaths for the CNC machine. Quick Press is used to create the die, and a prototype is tested. Simulations help fix any issues before production.

2. Tooling / Die Assembly

The individual components of the die are made and tested for fit. After that, CAMWorks or Mastercam is used to create toolpaths for CNC machining. The die parts are then assembled, and the complete die is tested to ensure it works correctly.

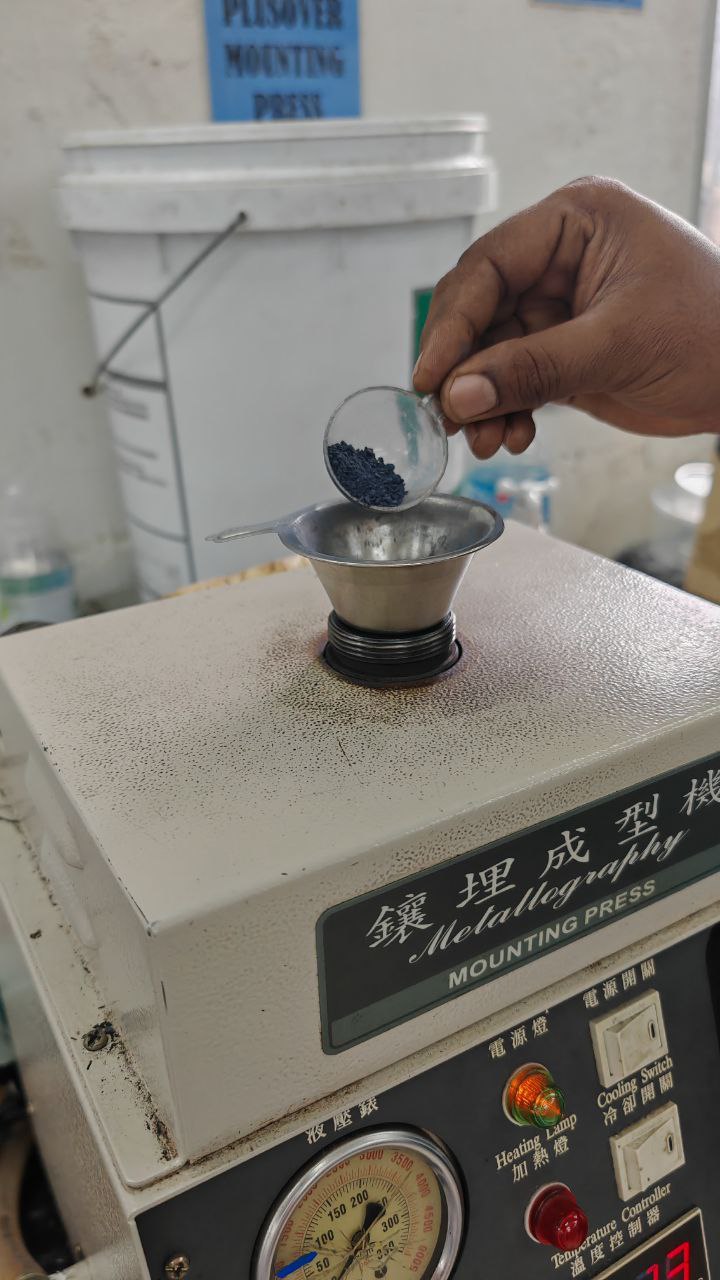

3. Quality Testing / Improvement

The die or tooling is tested by creating a prototype and checking how it works. If there are any issues, the design is adjusted. After fixing problems, it’s tested again to make sure it works right. Once it’s good, the tooling is ready for production.

4. Mass Production

In mass production, the die or tooling is set up in machines to make lots of parts. Quality is checked regularly, and any problems are fixed. Once everything works well, production continues until parts are made.